Commercial Production and Quality Control of Mesenchymal Stem/Stromal Cell-Based New Drugs

ZHANG Yun1,2,3, QI Qi1,2,3, HOU Ruizhen1,2,3, YANG Wenling1,2,3, ZHANG Yu1,2,3*

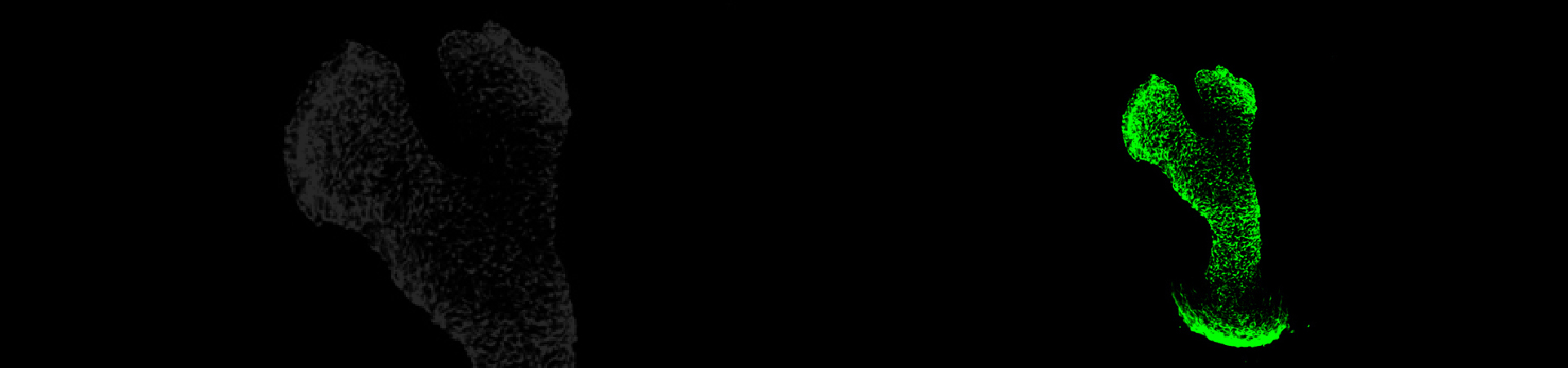

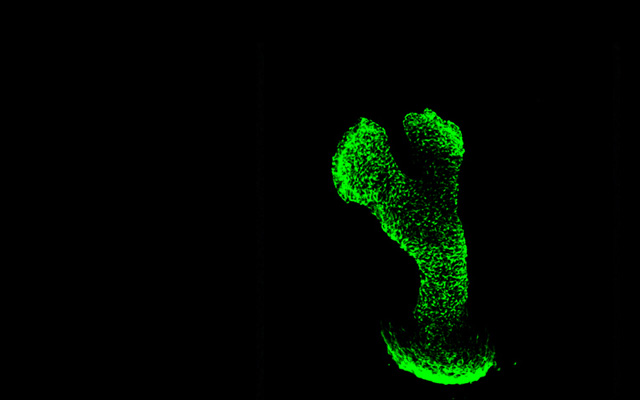

With the approval of MSCs (mesenchymal stem/stromal cells)-based drugs in China and the United States, establishing a stable, scalable, and GMP-compliant commercial production process along with robust quality control system is of paramount importance. This article reviews the current optimization directions and technical challenges in production processes and discusses key aspects of building a quality control system, providing references to ensure the safety and efficacy of MSCs drugs in clinical applications. Process optimization is crucial for cost control and meeting clinical demands. Key focuses include: adopting serum-free, chemically defined media to reduce batch-to-batch variability; developing novel bioreactors such as microcarrier-based suspension culture systems to enable automated, closed, and continuous production, thereby supporting scalable expansion; and optimizing harvesting, washing, and filling processes to maintain cell viability and enhance process robustness. Quality control requires establishing a risk management system covering the entire supply chain, strictly implementing material and release standards, and ensuring product safety, efficacy, and quality consistency from multiple dimensions. Additionally, stability studies should be conducted to define the shelf life and storage conditions, ensuring quality control and supply reliability during the commercial phase.

CN

CN EN

EN